HEPA Construction:

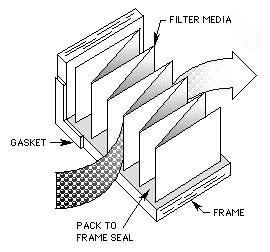

Although HEPA filter construction

can vary considerably, most HEPA filters consist of a rigid frame

into which a filter pack, constructed by folding a  continuous

sheet of media into closely spaced pleats, is sealed. Conventional

HEPA media is an all-glass paper which is composed of an extremely

large number of randomly oriented micro-fibers which utilizes

some fairly complex mechanical principles to achieve its effectiveness

on sub-micron particles (see principles of filtration). Because

of the density of the media, air flow is restricted and the pleating

is used to increase the amount of media (surface area) allowing

for a greater ratio of media to air flow. Over

continuous

sheet of media into closely spaced pleats, is sealed. Conventional

HEPA media is an all-glass paper which is composed of an extremely

large number of randomly oriented micro-fibers which utilizes

some fairly complex mechanical principles to achieve its effectiveness

on sub-micron particles (see principles of filtration). Because

of the density of the media, air flow is restricted and the pleating

is used to increase the amount of media (surface area) allowing

for a greater ratio of media to air flow. Over  the

years, filter manufacturers have developed different methods

and materials for maintaining the spacing of the pleats all in

an effort to optimize media surface area and reduce air flow

resistance.

the

years, filter manufacturers have developed different methods

and materials for maintaining the spacing of the pleats all in

an effort to optimize media surface area and reduce air flow

resistance.

In addition to sealing the

filter pack in the frame, the filter must be sealed when it is

installed in equipment in order to prevent air flow and the sub-micron

particles it contains from by-passing the HEPA filter. Like the

formation of pleats, filter manufacturers have developed different

methods and materials to accomplish this. The use of closed cell

neoprene gaskets is perhaps the most common method of sealing

the HEPA filter installation.

Many different HEPA filter

specifications and standards have been written for the myriad

applications in which HEPA filters have been put to use. From

UL-586 with environmental testing to ASME AG-1 with seismic qualification

for nuclear use, all have been developed to ensure the suitability

of a filter for a particular use.

IEST-RP-CC001.3

The most comprehensive guidelines

for HEPA filter construction is set forth in the Institute of

Environmental Sciences and Technology Recommended Practice IEST-RP-CC001.3.

The IEST Recommended Practice specifies many of the materials

used for HEPA filter construction and describes the various types

of filter packs as differentiated by the method used to maintain

the spacing of pleats. IEST-RP-CC001.3 also defines six levels

of performance and six grades of construction that distinguish

between the types of service the filter units may experience.

For example, Type "A" filter performance uses the Mil-Std-282

penetration test with a minimum efficiency rating of 99.97% on

0.3 microns whereas Type "F" filter performance is

for ULPA filters (ultra low penetration air) with a minimum efficiency

of 99.999% at 0.1 to 0.2 microns. Construction Grades range from

Grade 1 which meets severe environmental and handling tests to

Grade 6 for noncritical or nonsafety-related applications.

IEST recommended practices

are available for purchase from the Institute of Environmental

Sciences and Technology at www.iest.org.

Other Standards:

As was mentioned earlier, there

are many HEPA filter specifications and standards. Some have

been developed by individual companies for their own use, some

are for specific applications or industries. It is also common

to find some specifications or standards misapplied to a HEPA

filter or HEPA filtration, in general. Following is a list of

specifications or standards often found associated with HEPA

filters used in vacuum cleaners and a brief description of its

relevance.

ANSI Z9.2 - Fundamentals

Governing the Design and Operation of Local Exhaust Systems. Although this standard is often applied

to a vacuum cleaner as an exhaust system it does not specify

any HEPA filtration efficiency, construction or test requirements.

C-vac replacement HEPA filters will maintain the proper compliance

of any vacuum operating within the parameters of this standard.

ASME N509 - Nuclear Power

Plant Air-Cleaning Units and Components.

ASME N510 - Testing of Nuclear

Air Treatment Systems.

ASME NQA-1 - Quality Assurance

Requirements for Nuclear Facility Applications.

ASME AG-1 - Code on Nuclear

Air and Gas Treatment.

Written for nuclear power plants and nulear fuel cycle facilities,

this code includes standards for design, fabrication, inspection,

and testing of air cleaning equipment and components. Although

special filters can be manufactured to this code, standard HEPA

filters used in most vacuum cleaners do not meet this code and

the particular configuration of the filter may present other

specific limitations.

Mil-F-51068 - Filters, Particulate

(High-Efficiency Fire Resistant).

A military specification approved for use by all Departments

and Agencies of the Department of Defense, this specification

covers eight sizes and types of HEPA filters which must first

be qualified to be furnished under this specification. Although

some HEPA filters used in vacuum cleaners can be manufactured

with the materials and testing required by this specification,

there are no cylindrical filters included in its scope and most

standard HEPA filters used in vacuum cleaners do not comply.

Mil-F-51079 - Filter, Medium,

Fire-Resistant, High-Efficiency.

A military specification covering one grade of high-efficiency,

fire-resistant, filter medium normally used for compliance with

Mil-F-51068.

UL-586 - Standard for High-Efficiency,

Particulate Air Filter Units.

An Underwriters Laboratories standard for HEPA filters including

construction and environmental test requirements where samples

are tested for minimum performace characteristics. Filters employing

different materials or forms of construction from those detailed

may be determined to be in compliance with the standard if substantially

equivalent. Filters listed by UL under this standard may carry

a UL-586 label to identify compliance.

UL-900 - Test Performance

of Air Filter Units.

Underwriters Laboratories classifies air filters submitted

for testing as to flammability only. This standard investigates

the combustibility and smoke generation of a filter, not the

ability of a filter to remove airborne particles.

< Return to the Top >